09 June 2025

In the mineral processing industry, waste is often seen as a problem. But through a program called Energizing Granular Activated Carbon (GAC) from Waste to Eco-Efficiency, Harita Nickel has changed that view by turning used activated carbon into an efficient alternative energy source.

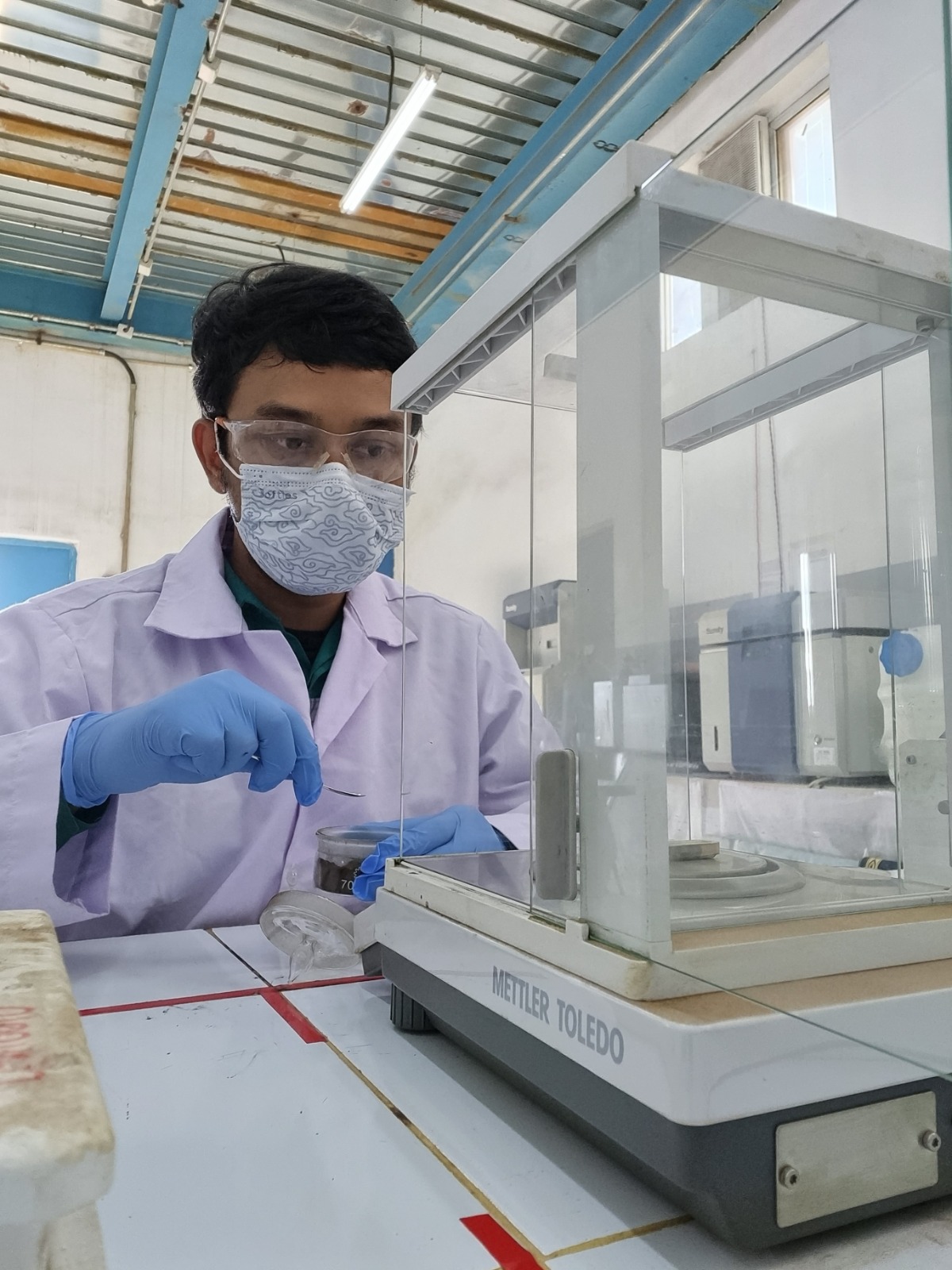

GAC plays an important role in the purification process, which is a continuation of the High Pressure Acid Leaching (HPAL) process, a technology used to extract nickel and cobalt from laterite ore. “GAC is made from coconut shells or fibers, which are eventually burned and turned into charcoal,” said Catur Prasetyo, Laboratory Staff at Harita Nickel’s Power Plant.

In this process, GAC helps remove organic compounds and contaminants from the sulfate solution. This improves the quality of the final product and protects the equipment from damage caused by impurities.

Once used, GAC becomes hazardous waste (B3), and Harita Nickel generates more than 1,300 tons of it each year. This challenge soon emerged: in addition to the high costs of handling and transportation, the buildup of this waste also poses risks to the environment and workplace safety.

“Instead of letting it become waste, we tried to revive this used GAC through controlled combustion, with emissions tested to meet the standards set by the Minister of Environment and Forestry Regulation No. 15 of 2019. The results were remarkable: not only did it produce heat that could be reused, but it also significantly reduced the volume of solid waste,” said Catur.

This project follows strict sustainability standards and was even included in Harita’s internal competition, the Harita Continuous Improvement (HCI) program. “The combustion of used GAC is done in a closed system at the Power Plant. The heat produced is used as an alternative fuel, partially replacing coal consumption,” explained Catur.

With this method, carbon emissions can be reduced, energy efficiency improved, and waste disposal costs minimized, bringing added value to mineral processing operations.

“GAC waste has the potential to be used as an alternative fuel because it contains 5,500 calories per gram,” said Adrianus Adityawardana, Superintendent of the Harita Nickel Power Plant.

Adrianus further noted that this innovation has the potential to be replicated across various Harita Nickel operational units. This initiative also strengthens Harita’s leadership in supporting the sustainability mission of Indonesia’s nickel industry, in line with advancing downstreaming through green innovation.

As pressure grows for extractive industries to be more eco-conscious, initiatives like this show real action. It’s not just about new technology, but a new way of thinking and beginning of new opportunities.

Go Top